The packaging and printing factory uses cartons to pack chicken products, and the cartons are discarded after the customer opens them. Now we switch to lightweight, small-sized woven bags with food-grade inner film instead of cartons. Without affecting product quality and quality, each woven bag is about 2 yuan cheaper than carton packaging, and a cumulative cost savings of 1.6 million yuan. At the same time, it can also reduce the energy consumption and cost of the product in the logistics and transportation process, and realize the win-win of the economic benefits of the enterprise and the social benefits. Tonghua’s specialized grain carton packaging “carton to woven bag” is just one measure of Shengnong’s packaging materials “”. The company’s annual purchase of packaging materials amounts to 230 million, of which cartons account for 65% and inner bags account for 20%. In recent years, the prices of raw materials such as carton packaging have continued to rise, and many companies have turned the pressure of rising costs into a driving force for transformation and upgrading, innovative development, and started lightweight and reduced-weight packaging.

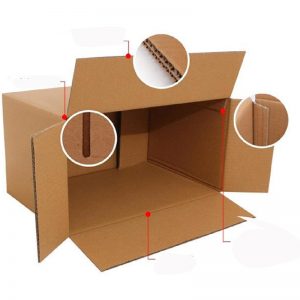

Miscellaneous grain carton packaging To produce a qualified heavy-duty carton, it is undoubtedly necessary to go through the processes of printing, molding, joining, and packaging. Why is the editor here focusing on the method of nailing heavy cartons? Because this is related to the forming of heavy cartons, it cannot be ignored. If the nail box is not well done, the box product can be said to be scrapped. Therefore, before the technology and quality control of the nail box, the selection of equipment, materials and operation technology can be said to be the top priority. It can be understood in this way that the quality problems of some carton packaging can be avoided as much as possible after the nail box is completed. Many people in Tonghua specialize in carton packaging for miscellaneous grains. Many people know that there are two main types of forming of heavy-duty cartons: gluing and nailing. With the increase of market demand, in recent years, in addition to the traditional single box nailing machine to complete the combination of carton forming, various equipment styles, models, structural performance, and manufacturing degrees and nail box effects are different. Fully automatic and semi-automatic nail box machines are also emerging. Single nail refers to the order of several single nail saws in the overlapping tongue of the carton. Double nails means two sets of nail saws side by side, and the reinforcement nails is a nail saw with a single nail placed between the two sets of double nails.

Miscellaneous grain carton packaging paper leads the future. Net news. With the rise of paper prices and the improvement of environmental protection awareness, the e-commerce and logistics industries have carried out the reform of express packaging. For example, Ning launched a shared courier box that can be recycled offline. Cainiao can reduce the use of packaging materials in the warehouse by 15% through an accurate algorithm. The built-in cushioning airbag put into production in Nanjing by Shentong Express can replace the plastic boxes of traditional cartons. Although social evaluations are mixed and will face certain cost pressures, the reform of express packaging is imperative. The emergence of recyclable cartons and various carton packaging alternatives will inevitably reduce the use of cartons in the express logistics industry. How will these changes affect the carton industry? Tonghua specializes in grain carton packaging. my country has surpassed Japan to become the world’s second largest producer of corrugated boxes after the United States. Moreover, the consumption of corrugated cardboard boxes in my country is in a stage of rapid growth. The consumption growth rate of both began in 2007. Both remain above 30%, and the growth rate is still rising year by year.